|

ANSSEN Metallurgy Group

|

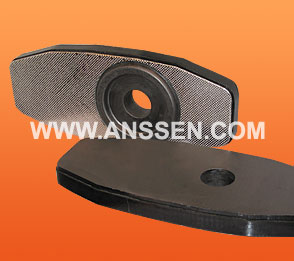

immerse sampler

| Payment Terms: | T/T,L/C |

| Place of Origin: | Liaoning, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

ANSSEN IMMERSE SAMPLERS To master the changing of the liquid steel composition

Anssen Immerse sampler

1. General introduction :

During the process of smelting, in order to master the changing of the liquid steel composition, sampling must be taken to get process analysis. During the pouring process, end production samples often are taken to get end production analysis. The progress of science and technology is pushing the progress of detection techniques. So studying fast process analysis methods and shortening sample taking time are the channels to raise analysis techniques and reinforce quality control.

2. Application range:

The immersing sampler is suitable for every steel factory to sample in tundish, ladle and horizontal casting.

3. Principle:

When the sampler instrument is put into the liquid steel, according to the floating continuous equation and static pressure effect of molten steel, the liquid steel will flow into the sample room by itself through the instrument taking the sample. The liquid steel in the sample room can be analyzed quickly and get C, Mn, P, S etc.

4. Main technical parameter:

(1)test success rate 90%.

(2)steel sample is full ,quality is thick ,smooth and no atmospheric holes.

(3)the time of taking a sample is 4 to 6 seconds in applied sphere.

5. Using Method:

(1)We can use a special measuring gun, then stick the gun or steel tube into the bottom of the sample instrument to prop up the turn of the gun.

(2)When measuring of the sample molten steel should have a bent about 60° to 65° then stick into the molten steel. The depth of sticking can be above 350mm,hold for 4 to 6 seconds.

(3)After taking the sample instrument from the furnace, knock it on the ground, so the sample of steel will fall down on the ground.

(4)It is best to take a sample when the molten steel temperature is above 1500° Steel

6. Sample size sample in cup(mm) :

Diameter thickness weight(g)

34 13(+/-1) 140g

7. Points for attention:

1.When taking a sample, first dig up dregs in order to provide blockage.

2.The depth and time when putting instrument into molten steel should be strictly carried out.

.jpg)

.gif)

.jpg)

.jpg)